For example, if your metal fits in a gap with 16 written in the front, that shows you have a 16 gauge metal. Once you find the right gap where your metal perfectly fits in, you should check the number in front. There’s a round cut out below the gaps those are not the right ones to use.

Each gap has a number written in front, and the principle is to place your piece in each gap until you find a place where it perfectly fits. There are gaps of different sizes around the gauge wheel. If you measure a nonferrous metal (metals without iron) like copper, gold, or silver, you should check the front of the gauge wheel and confirm it reads “nonferrous metal.” On the other hand, if you wish to determine the sheet metal gauge of ferrous metals (iron-containing metals) like cast iron, stainless steel, etc., ensure to choose a gauge wheel that reads “ferrous metal.” Use the right gauge wheel to get the correct measurement.

Auto stainless steel sheet metal how to#

To save you some time, here is a video on how to use a gauge:įrom the video, you could learn that there are basically 3 steps to measure a sheet metal: Step 1

There are three simple steps involved in this process, including: You can use it to measure both wire and sheet. Solution 2: Measuring Sheet Metal Thickness With WheelĪ gauge wheel is a simple tool with no moving part. That way, you’ll find the appropriate gauge of your metal. Step 3Ĭompare your result in inches with a sheet metal gauge chart. For instance, if you got a 60mm measurement, multiply with the said number, and you’ll have 2.3622 inches. You can convert the number obtained in mm to inches. Using the former will not provide the accurate measurements you crave. Remember that there are two different measurements on your tape, namely the cm and mm. Use the millimeter hash marks on your tape to find the thickness of sheet metal. There are three simple steps required in this, and they include: Step 1 Solution 1: Measuring Sheet Metal Thickness With Tape With a sheet metal gauge chart (is shown in next part), you can convert the gauge size to mm or inch.

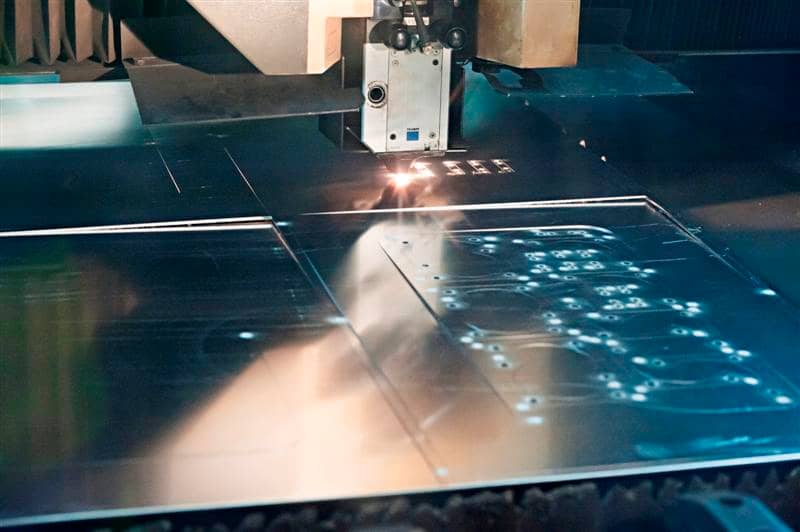

You can measure the sheet metals using regular tape or a gauge wheel. Now that you already know what a sheet metal gauge is, you should learn how to measure sheet metal thickness. If the sheet metal gauge is incorrect, there may be minor or catastrophic effects on your design. It is what determines whether an object will last or fail after short use. For instance, copper is a nonferrous metal, and ounces per square foot is its unit for measurement.Ĭhoosing a metal with the right gauge is essential to a successful design. However, ferrous metals have a different gauge from nonferrous metals. In many parts of the world, machinists measure sheet metal gauges in millimeters. Hence, metals with a large gauge number will be thin and vice versa. The higher the gauge number, the lesser the thickness of the material. Therefore, if you want to know how thick is sheet metal material, its gauge is what you should look for. When we talk of gauge in sheet metal manufacturing, we refer to the standard sheet metal thickness for a specific material. What is Gauge in Sheet Metal Fabrication? It also explains how to measure gauge and how to choose the right metal thickness for your fabrication. This article explains the meaning and importance of sheet metal gauge for sheet metal fabrication. A system called the gauge system determines this thickness. Perhaps you’ve seen sheet metals on several occasions used for roofing, welding, auto manufacturing, food industry, or in special sheet metal fabrication, and you’re wondering how the thickness of these smooth, beautiful pieces are determined.

0 kommentar(er)

0 kommentar(er)